The maintenance works in the area J1

Amer

Ahmed

Conservation

Assistant

Tell

Mozan/Urkesh Excavations

Extraordinary amounts of rainfall in the winter

and spring of 2019 in Hasake Provence, Syria

resulted in damage to the third millennium temple mound at Tell Mozan. A

portion of the revetment wall at the

junction of Mittani and EDIII construction

(excavation unit J5) was washed out (Fig. 1).Baulks in the lower plaza (excavation

area J1) collapsed ( Fig.2 ). After

consultations with the archaeological staff, we designed and implemented

temporary measures such as seds (water

diversion channels) to mitigate the damages.

At the end of May 2019 the rains abated and work to effect a more

permanent solution began. As the regular Mozan workmen were unavailable,

laborers from nearby communities assisted in cleaning, bagging soil, and

lifting stones. This phase took ten days with breaks for seasonal harvests.

Fig.1 . The crumbled wall in unit J5

Fig.2 . The unit J1 before the work

The works

included the following :

We

startedinJ5wherethesection of the Mittani revetment wall turns to join the EDIII revetment

wall. The huge stones were scattered on the ground with accumulated

soil on them (

Fig.3 ). Because we

lackedenoughexperiencetorestore

thiswall section,a temporary structure was built to

preserve the stones and protect the remaining sections of the revetment wall

until a full archaeological team returns to the site.

Fig.3 . The accumulated soil and scattered stones in

J5

The

first day, on Thursday 29 / 5 / 2019 :

We started

removing the soil which accumulated on the stones (Fig

.4). Thenwe

sortedthemtoputthebiggestonthebottomtoform

abase. Wewerevery careful to not disturb the soil that

remained from behind the revetment wall.(Fig.5). Thesoilwasreddishandfreeofstraw and sherds, but it contained a

few small stones. It appeared that none of the soil had

been sifted.

Fig.4 . Removing the

soil - the unit J5

Fig.5. The soil which remained behind the

revetment wall in J5

After cleaning and soil removal we reached the

last excavated level, escarpment 1 (^esc1). We placed a sheet of naylon

(plastic) on the escarpment to denote the start of the temporary repair (Fig.6 ).

Then we began the repair by using

the biggest stones as a base.

Fig.6.

Placing nalon under the stones in

J5

The

second day, on Saturday 1 / 6 / 2019 :

The work continued in the unit J5 but because of

the difficulty of lifting stones wehave

reliedonaninstrumentcalledal-Wensh (tripod

winch) tolift the stones (Fig.7); however,

we were having difficulty working because of the large stones.

Fig.7.

The al-Wensh in action in J5

After the stones were lifted and placed using

the al-Wensh, masonry mud (a mixture of soil,

straw and water) was used to fill the gaps between the stones (Fig.8 ).

Fig.8.

Filling the gaps between the stones with mud in J5

The third

day, on Sunday 9 / 6 / 2019 :

We worked in both units J5 and J1

.

InJ5,afterwefinishedplacingthestones

weneededtostrengthen the standing section of the

revetment wall of the temple as well as we could, cover the soil which remained

behindthewallofthetemple, and protect the reconstructed

section. Because we wanted the

repairs to have aesthetic appeal until it could be restored

properly, we built a

protective collar around the stones using burlap bags filled with the soilwhich

surrounded the collapsed wall section(Fig.9). The bags were

carefully placed until we reached the highest point possible ( Fig.10 ). Then we ran

out of the soil from the collapse.

Fig.9. Burlap bags filled with soil in

J5

Fig.10. The highest point reached on third day

in J5

As for

the unit J1, we began to remove the soil beside the damaged section

onboth

the southandeastsides(Fig.11).

We filled bags with this soil

which was to be used later to help protect the section against

further damage (Fig.12).

Fig.11.

The start of the work in unit J1

Fig.12.

Filling the bags in J1

The fourth

day, on Tuesday 11 / 6 / 2019 :

The process of removing soil beside the east and

south sides of the section in theunitJ1continued,aswellasplacingthebagsintheeasternside(Fig.13).as

tothesoilwhich

came from the section and will be used willbeusedfor

theprotectionofthetempleís

wall,we elected

to sift it to recover

sherds or other objects of archaeological interest (Fig.14).

Hammadi (our ceramics specialist) was interested in collecting every fragment

that appeared as a result of the sifting process (Fig.15).

Only sherds were recoveredand

personally bagged by Hammadi (Fig.16). The sifted soil was bagged

and transferred to the top of the

section and wall to be used later for building protective structures (Fig.17).

Fig.13. The work continues in J1

Fig.14. Sifting the soil in

J1

Fig.15. The pottery shards are collected by

Hammadi in J1

Fig.16. The pottery shards are put in plastic

bags in J1

Fig.17 . Transferring the soil bags to the top - the unit

J1

The fifth day,

on Sunday 23 / 6 / 2019:

We worked

in both J1 and J5.

InJ1,wecontinuedfillingbagswithsoilandplacingthemon theeasternandsouthernsidesofthesection(Fig.18). We also sifted and bagged soil and

transferred it to the top of the wall.

Fig.18.

Placing the soil bags at the foot of the section in J1

As for

the unit J5, after we ran

out of the soil from the collapsed pedestal which supported the Mitanni

wall, we used the soil which also had previously eroded from the section across

from the collapsed wall section to finish building the protective collar (Fig.19). The bags which have

been filled from the sectionís

crumbled soil were identified in a photo which I have

annotated by the Freehand Program (Fig.20).

Then we completed work on the collar (Fig.21).

Fig.19. Removing soil from the collapsed section

in front of the pedestal

Fig.2. Annotated photo showing which

bags came from the J5 section

Fig.21.

The completed protective collar in J5

The sixth day, on Tuesday 25 / 6 /

2019 :

We finished the work in J1, where the soil bags

have been placed and the surface leveled within the unit (Fig.22

and 23).

Fig.22. The process of leveling the soil in the

unit J1

Fig.23 View

of the completed leveling work in J1

The

seventh day, on Sunday 7 / 7 / 2019 :

After we finished the work inside J1, we moved

to the second phase which is to build a protective structure atop and in front

of the sections. We installed a framework of iron rods (Fig.24)

and covered it with tutia (corrugated metal sheets) (Fig.25),

which was attached to the iron rods in order to protect the sectionís

vertical surface from the rain in winter. In addition, we welded the

broken western door leading to J1

(Fig.26), thus finishing

construction work in J1 (Fig.27).

Fig.24.

Installing the iron rods in J1

Fig.25. Attaching the tutia to the iron rods in

J1

Fig.26. Welding the iron door in the unit

J1

Fig.27.

Iron rods and tutia secured in place in J1

The eighth day, Tuesday 16 / 7 / 2019 :

After installing the iron rods and tutia,

we covered the top inside edges of the tutia with soil (Fig.28)

to prevent leakage of rainwater

that may cause damages to the section. Then we placed tutia on the

top surface of the revetment wall running

from J1 through J5. Here we faced obstacles, because the large stones on

the wall-toppreventedusleveling the sheets of tutia, which were

being tilted and skewed (Fig.29).

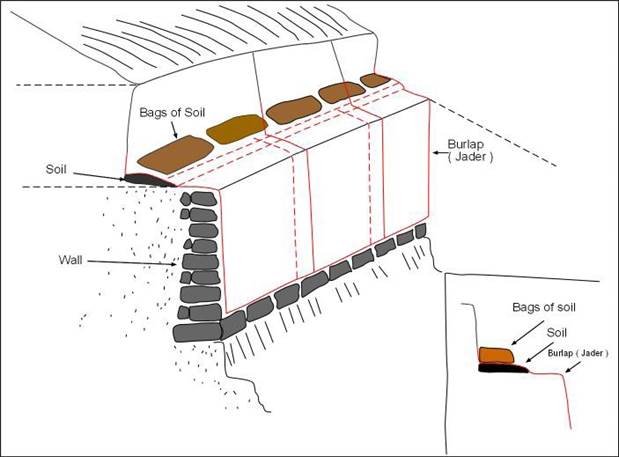

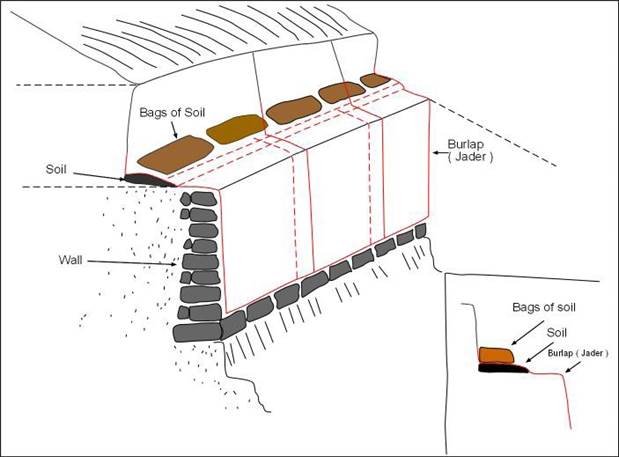

Becausewewouldhave

neededalargeamountofsoiltolevelthe

tutia,we decided to build a

curtain using jader (burlap) to cover all the wall from top to bottom and

anchoring it by bags of soil atop a layer of clay (Fig.30). This system will be installed at the end

of autumn and removed around the middle of March after the end of the tourist

season.

Fig.28 . Covering the

edges of tutia with soil in J1

Fig.29. Failed test of revetment wall protection

using tutia

Fig.30.

Recommended system to protect revetment wall

The ninth day, on Saturday 31 / 8 /

2019 :

After finishing work in the unit J1, where the

iron rods and tutia have been in-

stalled, we installed a burlap curtain backed with naylon (plastic) (Fig.31)

and attached by ribbons on the iron rods (Fig.32)

to protect the section from

further erosion. Themetal rods were spacedabout

180 cm apart, except in the

corners of the unit (northeast and southwest corners

) where the naylon

sidewas installed against the wall of the section. The unit J1 after finishing work on the ninth

day is shown in (Fig.33).

Fig.31.

Sewing the jader (burlap) with naylon

(plastic)

Fig.32.

Affixing the curtain onto iron rods by ribbons in J1

Fig.33.

The unit J1 from the northwest side

The tenth

day, on Sunday 8 / 9 / 2019 :

We painted

the tutia in the unit J1, where we have

mixed three colors (light brown,whiteandorange)(Fig.34),inordertomatch the color of the surrounding soil

(Fig.35 and 36).

Fig.34. Mixing the color

Fig.35.

The painting process

Fig.36.

The finished product after painting